Resources

Subscribe to our newsletter

i-5O Research Papers

Case Studies

Pride Mobility

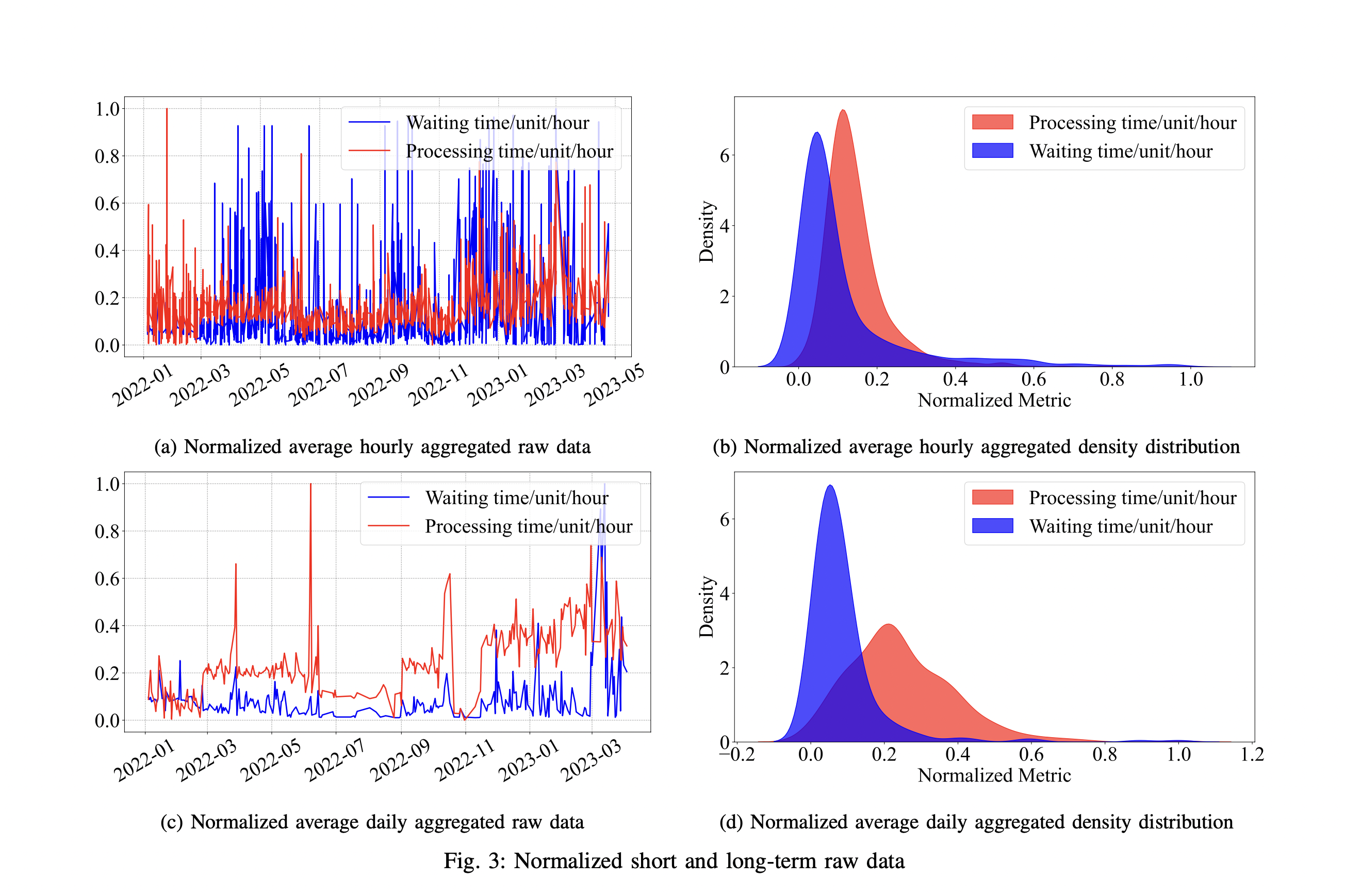

Pride Mobility is one of the leading manufacturers for power wheelchairs and other mobility products. i-5O Computer Vision System is used in their manufacturing facility at Duryea, Pennsylvania, where power chairs that are customized by their customers are manufactured. The data generated by i-5O has helped…

Suzuki

Suzuki Motor Corporation, headquartered in Hamamatsu, Japan, is a globally renowned automobile and motorcycle manufacturer. Founded in 1909, Suzuki has established a legacy of innovation and quality, offering various vehicles that cater to different market needs while maintaining a strong commitment to…

Blogs

Frequently Asked Questions

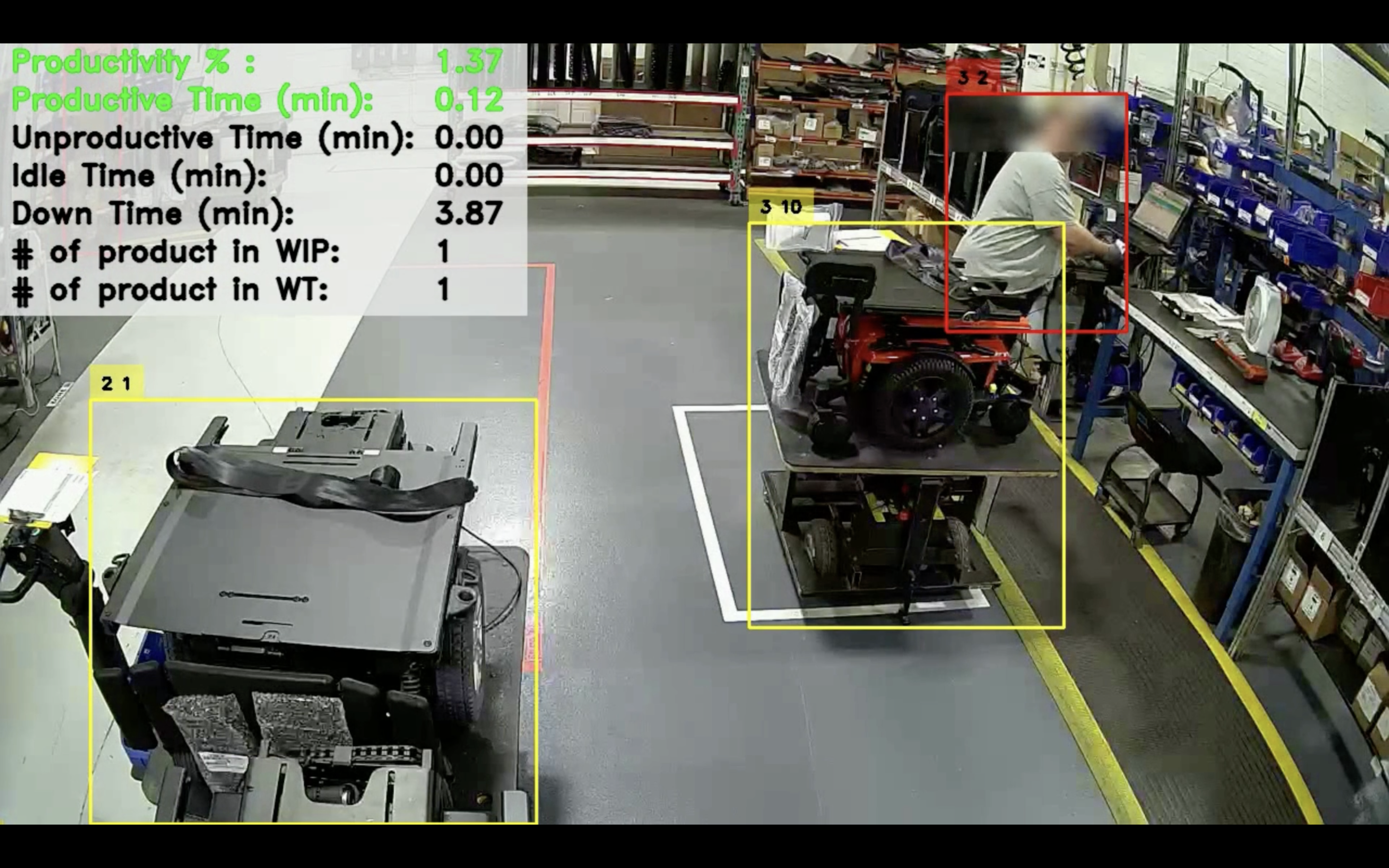

IFIVEO possesses an exceptional capacity to capture diverse video data across all aspects of the manufacturing floor: human presence, materials in use, and machinery operation. Adapted to each client's specific requisites and manufacturing hurdles, we meticulously monitor the essential components. Through the utilization of AI-driven video streams, we not only measure workstation activities with precision but also generate comprehensive assembly datasets. These datasets subsequently fuel real-time analytics, furnishing invaluable insights into the dynamics of manual assembly lines.

Ensuring your data is our utmost priority. As an ISO 27001 certified and GDPR compliant company, we uphold stringent data protection and privacy protocols. This certification serves as an evidence of our unwavering dedication to maintaining the highest levels of information security. Your trust in us is paramount, and we ensure that your data remains secure within our care.

Our system operates under a Software as a Service (SaaS) model, presenting a flexible monthly or annual subscription plan that caters to the specifics of your manufacturing requirements. The pricing structure takes into account the intricacies of your unique use case. As part of the package we can seamlessly integrate with your existing cameras if available. To receive a quote that perfectly suits your environment, please reach out to us at contact@ifiveo.com

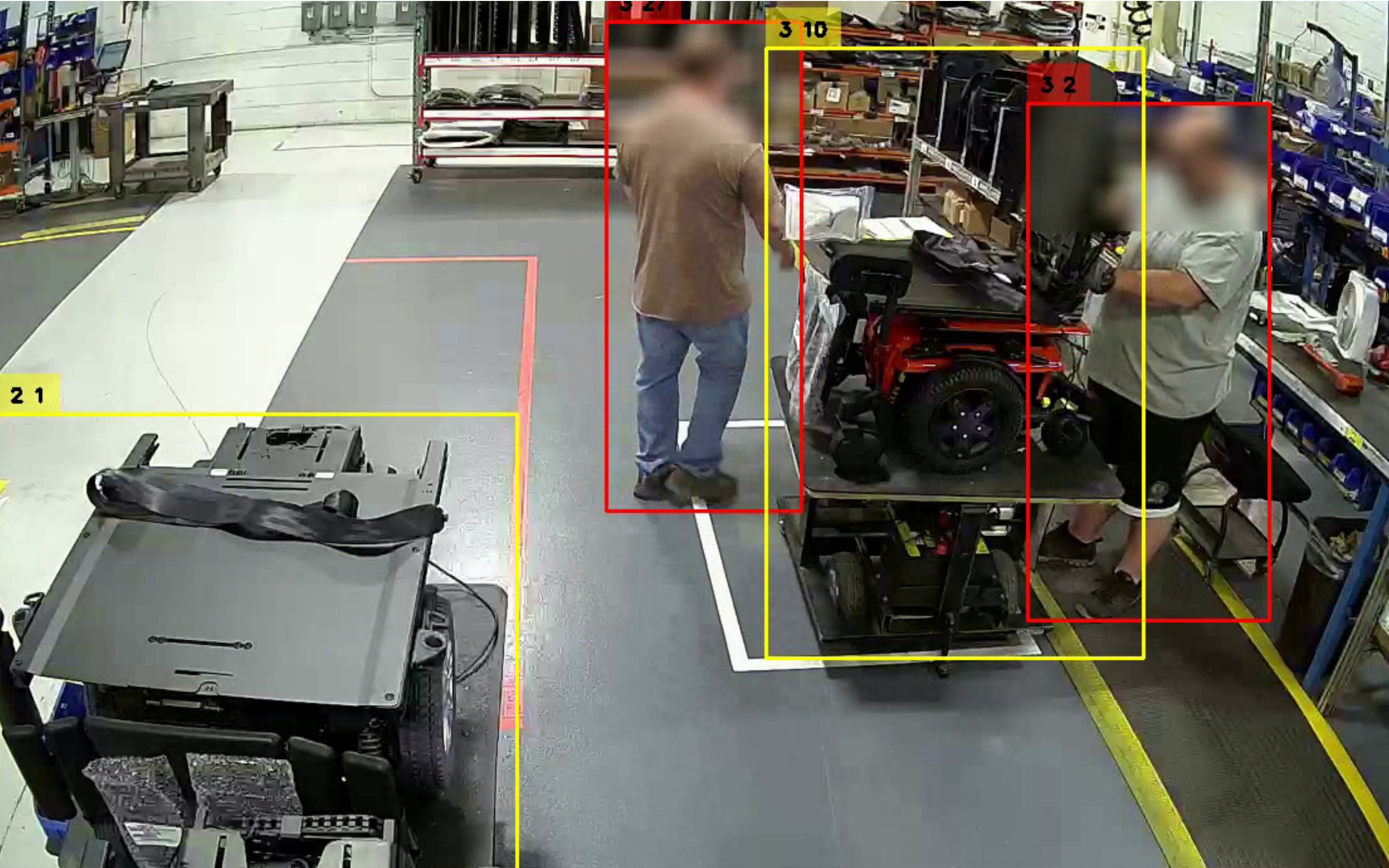

Safety of our line associates is of paramount importance. Prior to system implementation, we provide comprehensive onboarding and training for your workers to ensure they understand that this system is designed to assist and support them, rather than monitor, track, or compromise their identity. Its primary purpose is to facilitate continuous improvement in operations. Furthermore, the footage intentionally blurs the faces of workers. This protective measure shields their identities while enabling us to analyze workflow for enhanced process efficiency. Our system respects the dignity and contributions of your line associates, and we are committed to maintaining a positive and supportive atmosphere on your manufacturing lines.

Indeed, the integration of the IFIVEO platform with external software and tools can be tailored to your specific needs. We understand that each client's requirements may differ, and as such, we offer a customized approach to ensure that the integration aligns precisely with your existing systems and workflows. This personalized integration strategy ensures optimal compatibility and functionality for your unique manufacturing environment.

Our system's uniqueness lies in its ability to capture and analyze video data of key manufacturing components: people, materials, and machines. Based on the client's specific requirements and production challenges, we focus on tracking the necessary elements. Through AI-driven vision software, we automatically measure activities at workstations and create comprehensive insights and alerts in real time.

Try it for Yourself

Schedule your 1st Free Consultation and Start your AI Journey Today